Discharge conveyors

When emptying bunkers and silos, high forces act on the conveying elements. The bulk material industry relies on the use of high-strength and wear-resistant HEKO round steel chains, HEKO forged fork link chains or HEKO bushed conveyor chains here.

A distinction is made between scraper conveyors with reinforced, wear-resistant scrapers and apron conveyors. In the apron conveyor version, solid steel belt cells are used, which are adapted to the specific requirements. The highest standard of construction, optimum material selection and precise manufacturing technology guarantee reliable operation and a long service life. This also applies to the sprockets and rollers manufactured by HEKO.

We would be happy to help you with your conveying task in a customer-oriented, target-oriented and reliable manner.

Bucket elevators

High-performance bucket elevators play a key role in bulk material conveying technology. They are often used at critical points in industrial processes and enable energy-efficient, dust-free and careful vertical transportation of large bulk material streams.

This is an ideal field of activity for HEKO because it requires sophisticated technology by HEKO: careful material selection, precise processing and a long service life. Depending on the grain size and temperature of the bulk material as well as the transport task, HEKO uses round steel chains, double-strand bush conveyor chains, central chains or steel cord belts in OEM quality as traction mechanism. A wide range of connecting and fastening elements, elevator buckets, drive and tension sprockets as well as dust-tight return devices complete the product range. The products are all perfectly tailored to each other and to the specific conveying task. They are always functionally reliable and efficient. And, above all, they are always highly variable and adaptable. We look forward to advising you!

Rotary kilns

Rotary kiln chains by HEKO. Available as ring chains or in an oval design. Dimensions and qualities for every furnace area. Completed by shackles, hangers and accessories in forged and casted designs. Ideal for heat exchange and material transport, as a dust curtain or for cleaning the furnace walls. Manufactured in a large variety of materials. Made from different types of steel, including austenitic manganese steel. Therefore, these products are ideally suited to a wide range of furnace systems. Preferably used for rotary kilns that operate with the wet process. Also used all over the world in long dry kilns and in the paper industry. Appreciated everywhere for their excellent combination of stability, durability and reliability. HEKO is the market leader in the field of heat-resistant rotary kiln chains for a reason.

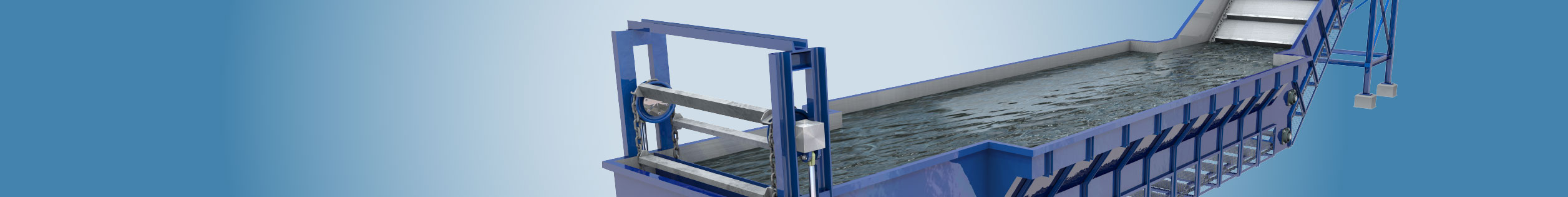

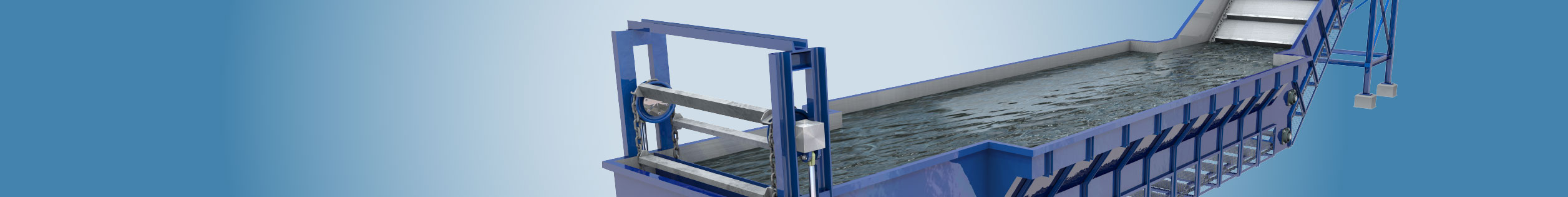

Ash removal systems- deashers

Ash removal systems play a key role in the power plant industry. The suitability of a method is measured, among other things, by whether it is reliable, simple, efficient and profitable. Regardless of whether dry or wet ash removal is used, the focus here is primarily on harmonising the processes, from collecting, extinguishing or cooling down to storage in the ash bunker. The efficient and trouble-free transport of slag granulates, ash or smelting residues requires chain conveyors that are optimally tailored to the material which needs to be conveyed.

For this purpose, HEKO supplies the most suitable endless chain strands, alternatively with type TS, type SMO or other attachment versions. The TS attachment for chains in accordance with DIN 764 and the SMO version for endless chains can also be used in reversing operation. Both versions are easy to shorten, offer simple mounting of the and make a reliable contribution to smooth transport.

HEKO – You can rely on us.

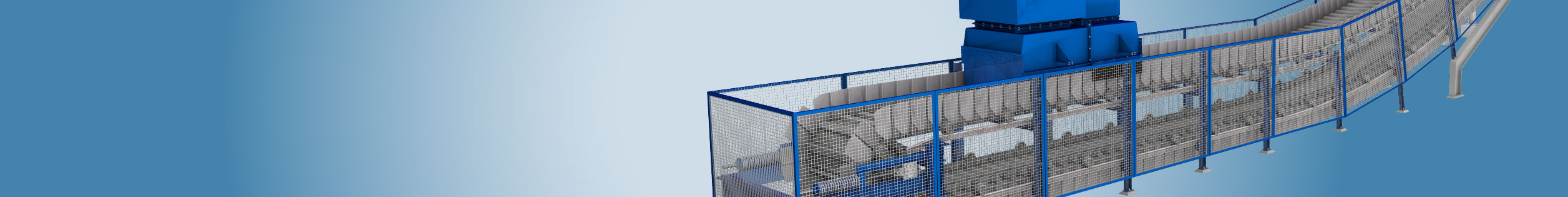

Stockpile discharge conveyors – Reclaimer conveyors

One thing is clear: the individual components themselves do not yet result in a functional system. However, it is also obvious that material quality and the design advantages of individual elements set the decisive parameters when the productivity and efficiency of a reclaimer conveyor system is put to the test. In this way, HEKO block link chains and bushed conveyor chains, carriers and shovels, as well as sprockets and rollers make a decisive contribution to success and all these components are individually adapted to your needs and your application. The result: optimised service life, low maintenance costs and a long service life.

Coal feeder

Coal feeders are used in the power plant industry for mill coaling. Usually, the coal feeders are connected to the respective coal bunker via a coal chute. The coal is transported in the upper run by direct removal from the material column on the upper run. The height of the removed bulk material flow can be adjusted by means of a manual layer height adjustment. In front of the drive station the extracted coal falls into the lower run and is transported to the discharge chute in the lower run. The direct removal of the rough coal from the coal chute and the simultaneous load placed on the upper and lower run pose a special challenge for the traction mechanism and conveyor components. Here, high-strength and wear-resistant HEKO round steel chains or HEKO forged fork link chains as well as specially-reinforced scrapers and carriers have been tried and tested many times. Sprockets adapted to the respective chain system complete the HEKO portfolio. On request we manufacture products according to your individual specifications.

Scraper conveyors

Scraper conveyors are high-performance conveying machines for the horizontal and ascending transport of very differentmaterials, which are sometimes difficult to handle. The applications are as varied as the respective chain system is individual.

No matter whether you are using a round steel chain, forged fork link chain or bushed conveyor chain, HEKO has the right solution here. Always wear-resistant, robust and reliable. Scrapers in simple or reinforced designs with a width of up to 3,000 mm, equipped with sacrificial anodes in case of extreme corrosion, as well as sprockets which are tailored to the chain system and the individual case, complete the HEKO portfolio.

On request we manufacture products according to your individual specifications.

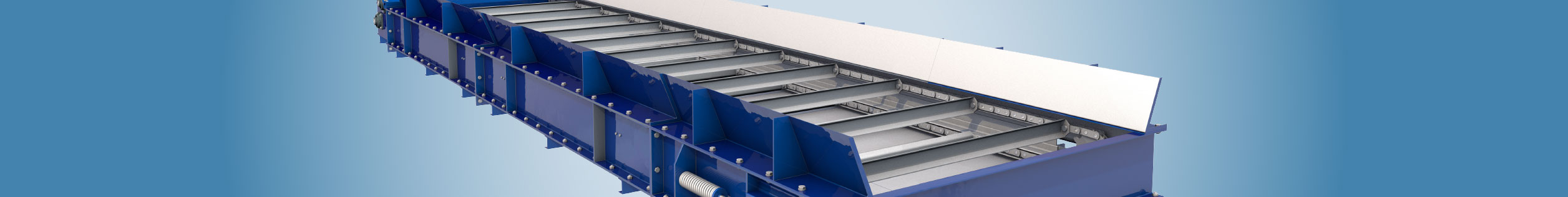

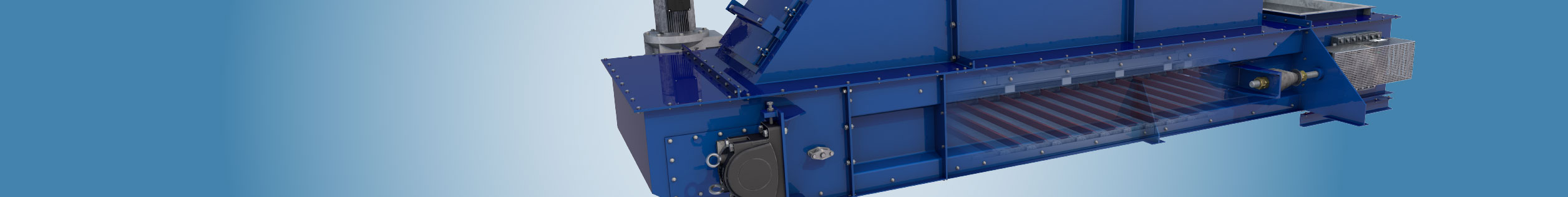

Pan conveyors

Modern pan conveyors are high-performance conveying machines for the horizontal and ascending transportation of large bulk material flows. As traction mechanism, the tried-and-tested HEKO apron conveyor chains in a wide range of different breaking loads and designs are used. Modern production technologies as well as load-compatible dimensioning and material selection guarantee a long service life and high level of reliability. The high-strength and precisely-manufactured HEKO steel cells designed as deep drawn pans, deep drawn pans with baffle plates and buckets ensure a tight panel connection and reliable functionality of the conveyor. Exchangeable rollers with sealed roller bearings as well as drive and tension sprockets complete the HEKO product range. In addition to our own standard, HEKO also offers all components in a customised design which is custom-made to your specifications.

Pivoting pan conveyors

With the option of different positions for the material feeding and discharge, pivoting pan conveyors enable the distribution of bulk material streams to several silos or bunkers with one conveyor. Simultaneous conveying on the upper and lower runs facilitates particularly efficient bulk material handling. As traction mechanism, the long-established and tried-and-tested HEKO pivoting pan conveyor chains are used with a wide range of different breaking loads and designs. Modern production technologies as well as load-compatible dimensioning and material selection guarantee a long service life and a high level of reliability. The high-strength and precisely-manufactured HEKO pivoting pan conveyor cells guarantee reliable conveyor functionality. Exchangeable rollers with sealed roller bearings as well as drive and tension sprockets complete the HEKO product range. HEKO will be pleased to offer you the components which go with your pivoting pan conveyor and we can tailor these individually to your specifications.

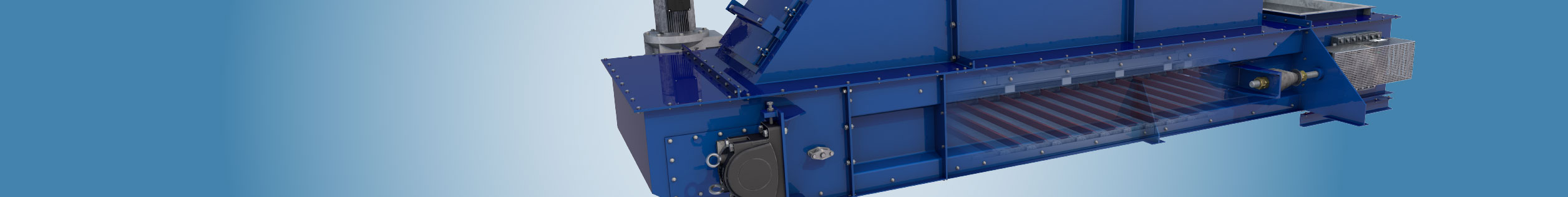

Drag chain conveyors

The highest level of efficiency, power density and the needs-based design of our products make them ideal components in the field of conveyor technology. For the troughed chain conveyor sector, our range of products includes a wide selection of troughed chainconveyor chains, designed as highly wear-resistant round link chains, optimised forged fork link chains or bushed conveyor chains. We supply the matching drive sprockets made from alloyed special steel with hardened chain contact points and hubs made from steel or stainless steel, preferably with interchangeable sprockets. The advantage of these multi-part sprockets: easy replacement of wear parts, no disassembly of the shaft and thus minimised downtimes. In other words: HEKO components for troughed chain conveyors are technically sophisticated, variable, reliable and therefore customer-friendly in the best way.