Our production:

Concentration on core competencies

Top performance is always the result of hard work, determination and competence. These are the exact characteristics that have shaped HEKO over a long period of more than a century. The deliberate concentration of all resources on one topic, bulk material conveyor technology, is also characteristic and helps to achieve the objectives.

This deliberate restriction to our core competence is also our strength because it guarantees that customers all over the world can rely on the superior expertise and the permanent innovative further development of our products.

A leader in technology, systems & processes

At the moment, at three locations in North Rhine-Westphalia, we manufacture a wide range of conveyor chains, sprockets, fastening elements and assemblies for conveyor systems in a production area comprising approx. 45,000 m². The technology, systems and processes in use are state of the art and our modern heat treatment sets standards.

Heat treatment

The ideal hardness for market success

The heat treatment of chains and other elements is preferred in the production process and there are good reasons for this. The quality of the hardening, for example, has a significant impact on the service life of components and thus the economy of the conveyor system. For this reason, a heat treatment process is selected that is precisely tailored to the specific requirements and material properties of a component.

Overall, the following heat treatment techniques are available:Case hardening

- Induction hardening

- Quenching and tempering

- Nitriding

- Vacuum heat treatment

- Improved conditioning of heavily used parts

HEKO sets new standards in heat treatment with low-pressure carburising and high-pressure gas quenching. A technology that has so far proven itself in gear components and other precision components as well as in the hardening of warp-critical and thin-walled elements. It is being used by HEKO for the first time in the world in the chain industry with great success.

The advantages of this modern heat treatment technology are:

- Dimensionally stable and low-warp heat treatment

- Better hardening and toughness with homogeneous material structure

- High precision of the heat treatment and the process sections

- Cleanliness and environmentally-friendly

- Possible methods of vacuum heat treatment:

• Case hardening

• Hardening

• Tempering

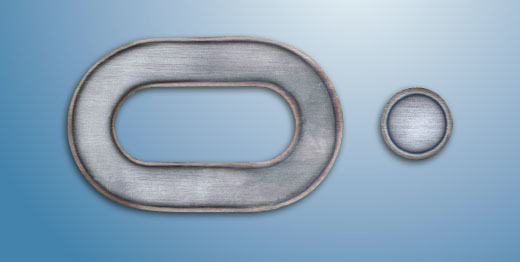

• AnnealingDescriptive diagrams about the very consistent C profile and the hardness profile within one batch:

- C profile 15 CrNi 6

- Hardness profile 15 CrNi6

- Achievable core hardness with different case hardening steels

Technical specifications:

- Maximum batch size: 1,000 x 600 x 750 mm

- Maximum batch mass: 800 kg

- Maximum temperature: 1,250 ° C

Low-pressure carburisation

Service for manufacturers of highly wear-resistant components

HEKO has had a significant focus on heat treatment since the 1930s. Therefore, experts in the field are highly aware that we are hard to beat in terms of experience and expertise in low-pressure carburisation. It is all the better that others can benefit from it! The flexible properties of our Modultherm heat treatment system allow a fast changeover between a very wide range of batches.

Since HEKO also has sufficient capacities, we can make the special advantages of this advanced hardening technology available to other manufacturers of wear-resistant components too.

Case hardening

The security of perfect conditions

The latest generation of vacuum chamber furnaces with helium quenching and a capacity of up to 800 kg unit weight guarantee the best possible heat treatment and give our customers the security of first-class product conditions:

- Highly wear-resistant surface layer with at least 800 HV surface hardness for conveyor chains

- High fatigue strength

- High breaking strength thanks to a fine-grained, tough core

- Highest dimensional accuracy

Inductive Surface Hardening

Hard Edge

The special process of inductive heating allows for partially limited heating (austenitising) and the quench hardening of parts. In this way, the surface layers of individual elements with working dimensions of up to 1,000 mm in diameter and 700 mm in height can be hardened if required.

Nitriding Process

Improved Wear and Corrosion Protection

By investing in a new furnace system, the number of heat treatment options on offer could be systematically expanded. Our customers benefit in that with this plant, the following nitriding processes up to a working temperature of 750 °C are now available:

- Nitriding

- Carbonitriding

- Preoxidising

- Reoxidising

The main objective of these treatments is to protect against wear or corrosion. Corrosion resistance can be further improved through cooling in oxidising atmospheres.

The advantages of these processes include:

- High wear resistance with adhesion

- Creation of corrosion-resistant layers

- Up to 400 °C heat resistance of the nitriding layer

- Partial nitriding possible

- A batch size up to 1,100 x 1,500 x 900 mm is possible. The maximum batch weight is 2,500 kg.